Definition of Electrical Enclosures

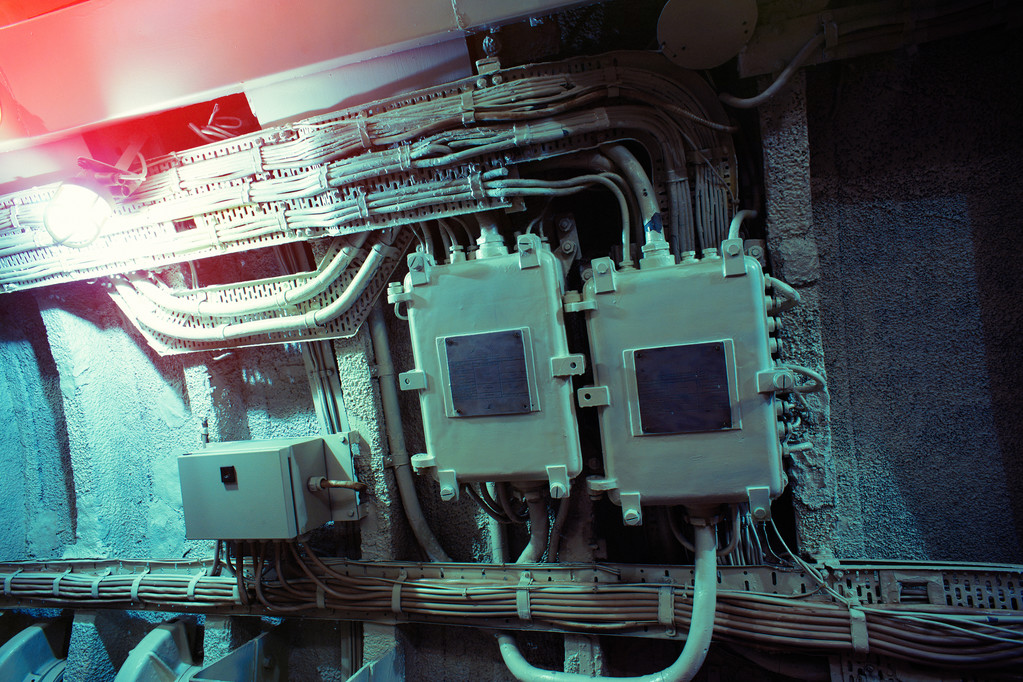

An electrical enclosure is a box or cabinet that houses electrical components and provides protection against dust, moisture, and other environmental hazards. These enclosures are typically made of metal or plastic and come in a variety of shapes and sizes. Electrical enclosures not only protect the components inside from damage but also provide additional safety for personnel who may come into contact with the equipment.

The purpose of an electrical enclosure NZ is to protect personnel from potential shock risks associated with electric current as well as provide an environment that meets all relevant safety regulations. To ensure safe operation, the enclosure must be designed to contain any arcing or sparks created by live parts within the box, prevent the entry of foreign objects such as liquids or dust which could cause short circuits, resist corrosion due to environmental conditions such as rain or snow, and keep out pests such as rodents which can cause damage by chewing on wiring insulation.

When selecting an enclosure for a particular application it is important to consider several factors including size & shape requirements, material selection (metal vs plastic), type of mounting (e.g., wall-mounted vs free standing), NEMA rating (national electrotechnical commission ratings), ingress protection rating (IP code) for resistance against water & dust infiltration, UL listing certification for compliance with fire.

Types of Electrical Enclosures

Electrical enclosures are essential pieces of equipment used to protect electrical components from various environmental conditions, such as dust, moisture, heat and vibration. They come in a variety of shapes and sizes for different applications. Depending on the function they need to accomplish, there are many types of electrical enclosures available on the market today. This article will discuss some of the most common types.

- Wall-Mounted Enclosures: Wall-mounted enclosures are designed to contain and protect electronic components while providing access to them through a door or panel with removable cover plates. These are typically lightweight and can be mounted easily onto walls without requiring any additional support structure. Wall-mounted enclosures provide safety by preventing accidental contact with live parts inside while also protecting against external elements like dust, dirt, water and other contaminants.

- Floor Standing Enclosures: These larger units offer more protection than wall-mounted models due to their substantial size and weight; some stand up to 8 feet tall! Floor-standing enclosures are commonly used in industrial settings where larger equipment is stored or maintained indoors but have found their way into consumer applications as well – think server rooms or home automation hubs! They provide excellent protection from electromagnetic interference (EMI) by containing sensitive electronic components inside the ground.

Uses and Benefits of Electrical Enclosures

Electrical enclosures and electrical switchboards are a critical component in any electrical system, providing protection for the components and wiring within. This is especially important in industrial settings where hazardous materials or large amounts of electricity can be present. Without properly designed enclosures, it can be difficult to maintain safe working conditions and prevent accidents.

The most common use for electrical enclosures is to protect the electrical components inside from dust, debris, moisture, and other environmental elements that could cause damage or malfunction. Electrical enclosures are also used to protect people from coming into contact with exposed wires and potentially dangerous voltages. In industrial settings, they help reduce noise levels by containing loud machinery and equipment inside a protective box-like structure.

When selecting an enclosure for a particular application, there are several factors to consider such as size (width/length/height), material type (aluminium or steel), ingress protection rating (IP rating), corrosion resistance ability (NEMA rating), temperature range capability (-60°C – +85°C) etc. The selection depends on the environment that the enclosure needs to operate in as well as its intended purpose. For example, if you need an enclosure for outdoor use then you may want one with a high IP rating so that it can withstand harsh weather conditions.

Considerations for Choosing an Electrical Enclosure

When it comes to the electrical components of your project, choosing the right enclosure is essential. Electrical enclosures are used to protect and house sensitive electrical equipment from the elements and other external forces. Ensuring you choose an enclosure that meets your needs can help prevent damage to the equipment, injuries, or other costly problems.

When selecting an electrical enclosure for your project, there are many important factors to consider. First, you should consider what type of protection is needed for the specific application requirements. Different enclosures offer different levels of protection such as dust-tightness, water resistance, corrosion resistance and more. If a particular environment has particularly high temperatures or humidity levels then a special type of enclosure may be required for those conditions too.

The size and shape of an electrical enclosure should be determined based on its purpose and how much space it will need in order to fit all components inside safely without any interference from other objects in close proximity such as pipes or wires. The size should also take into account any additional room needed for maintenance or repairs if they become necessary at a later date; this could mean having larger cutouts than initially expected in order to make sure enough space is available when required further down the line.

Conclusion

In conclusion, electrical enclosures are an essential part of any electrical system. They offer safety, protection and organization for all types of components, from wires and connectors to switches and circuit breakers. Their versatility makes them ideal for use in any environment or application where electricity needs to be managed safely. With their wide variety of styles, sizes, materials and features available, there is sure to be an enclosure that meets the needs of every project.